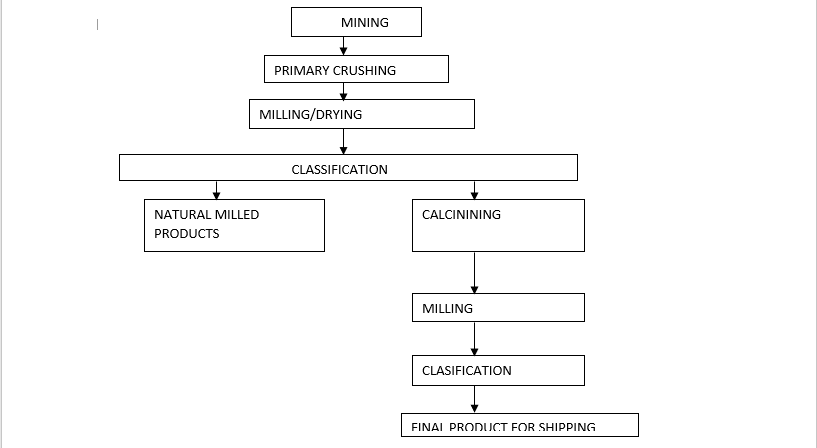

PRODUCT PROCESSING

In diatomite ore mining, we employ both open –pit quarrying, surface mining methods and underground mining. The most versatile method that we adopt is surface mining, which is cheaper and safer than underground mining and leads to high quality ore. Where the diatomite sequence is thick, benches from 1.5 to 9 m in height are developed. Benching not only facilitates the removal of ore and waste but also permits immediate access to many more layers .Prior to mining, the ore strata are carefully identified in the quarry faces through sampling and evaluation programs that determine and confirm the suitability of each individual stratum, geological and geochemistry methods are employed to determine and confirm deposits depth, physical and chemical properties. The ore-grade strata can then be rated by quality and carefully segregated from the lower quality waste units using mechanized equipment.

Because diatomite is soft, easily broken sediment, ores are typically dozer ripped or broken from the face by power shovel. Blasting of the ores is neither needed nor possible because of the inherent softness of commercial quality diatomite, its porosity, and its absorptive nature. The broken material is loaded by excavator into haul trucks for transport to either the crude storage area or the waste piles.

Milling Methods

The objectives of milling are twofold: to disaggregate the crude ore into individual diatoms while preserving the delicate diatom structure, and to remove as much no diatomaceous contamination as possible. Ore is gently crushed in hammer mills to reduce feed size to approximately –1.27 cm. The crushed feed is then conveyed by heated air into milling fans and simultaneously milled and dried.

Thermal Processing Methods

Calcined products

Diatomite is thermally processed, or calcined, to achieve fundamental adjustment of particle structure and particle-size distribution. Calcination in a rotary kiln, with or without the addition of a fluxing agent, removes organic matter and reduces the percentage of fine structure through incipient fusion, thereby reducing surface area through the loss of fine structure. Average particle size is increased through sintering or agglomerating the individual diatoms and fragments. After calcinations, there is further milling and air classification, the coarser fractions or cyclone products are collected for use as filter aids. The finer baghouse products are used as fillers. Permeability and flow through rate of the powders used for filtering are thus increased and a more diverse spectrum of products is made possible through classification. Calcination produces a colour change as well as the modification of other properties described previously. Diatomite is calcined without adding a fluxing agent at temperatures that range from 870° to 1,100°C to produce pink or off-white straight calcined product grades. The straight calcined grades of filter aid exhibit flow rates faster than the natural grades but achieve lower filtrate clarity. Calcination at temperatures up to 1,200°C with a fluxing agent added produces white-colored product and further increases the flow rate of the coarse fraction filter aid grades. The fine fraction recovered from the baghouse is sold as white fillers. We use soda ash (sodium carbonate) as the fluxing agent. Temperature, amount of flux used, and retention time in the kiln are used to control the particle-size distribution. In general, fluxing agent is added at 4 wt % to 6 wt % of the feed raw diatomite ore.

Uncalcined products

The processing of uncalcined or natural-grade diatomite consists of crushing and drying. Crude diatomite commonly contains as much as 40 percent moisture, in many cases over 60 percent. Primary crushing to aggregate size (normally done by a hammer mill) is followed by simultaneous milling- drying, in which suspended particles of diatomite are carried in a stream of hot gases. Flash and rotary dryers are used to dry the material to a powder of approximately 15 percent moisture. Typical flash dryer operating temperatures range from 70

to 430 C (150 to 800 F). The suspended particles exiting the dryer pass through a series of fans, cyclones, and separators to a baghouse. These sequential operations separate the powder into various sizes, remove waste impurities, and expel the absorbed water. These natural-milled diatomite products are then bagged or handled in bulk without additional processing.

Diatomite processing